- Specialty additives

- Additive formulations

- About us

- Applications

- Contact

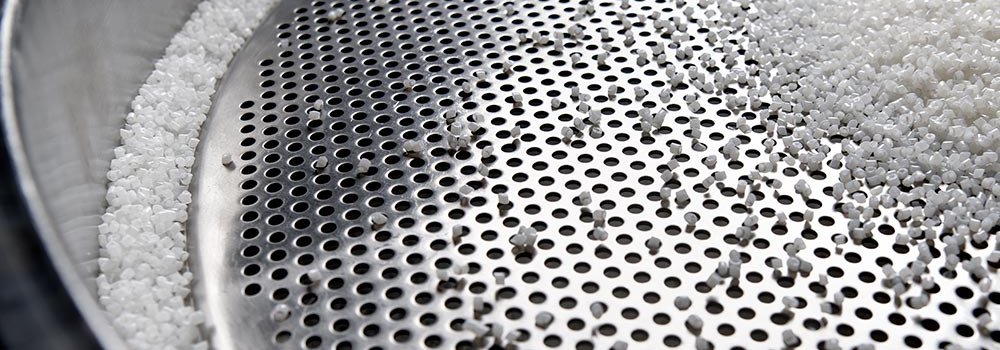

ADEKA Polymer Additives Europe offers a full range of solid and liquid primary and secondary antioxidants.

Range

Physical blends of stabilizers with different stabilization mechanisms are the state of the art today. The overall effect of two stabilizers combined is better than what would be expected based on the sum of effects of each component alone.

Range

Phenolic antioxidants are radical scavengers which prevent thermal degradation of many organic materials such as polymers. Their effectiveness increases when used in combination with phosphites, thioethers and light stabilizers.

Range

Phosphites are efficient decomposers of hydroperoxides that are formed during the autooxidation of polymers. Phosphites are especially used in melt processing where they are added in blends with hindered phenolic antioxidants. Such combinations are more effective than hindered phenol alone.

Range

Sulfur-containing antioxidants, also referred to as thioethers, react with and decompose polymer peroxide to inert substances. These so-called ‘secondary anti-oxidants’ exhibit a remarkable synergism in combination with hindered phenols to offer additional long term stability.

Polymers are increasingly used in new and varied applications where specific mechanical, thermal and electrical properties are required. Particularly in E&E, transportation and building applications another important property is flame retardancy to prevent the burning of polymers such as PE, PP and PA. ADEKA Polymer Additives Europe offers a range of halogen-free flame retardants that also enable environmental requirements to be met.

Light stabilizers are a group of additives that have been developed to minimise or prevent the damage to plastics caused by exposure to the environmental parameters of light, heat and air.

ADEKA Polymer Additives Europe offers a complete range of light stabilizers:

• Benzophenones

• Benzotriazoles

• Hindered Amine Light Stabilizers (HALS)

These light stabilizers provide protection from UV radiation by interfering with the physical and chemical processes of light-induced degradation according to different mechanisms.

Range

Hindered amines show excellent UV protection by scavenging free radicals generated by photo degradation. When to use HALS or other light stabilizers depends on the processing requirements and demands of the end user. In some cases, combinations of light stabilizers have shown superior performance.

In general terms, stabilizers containing sterically hinderd amines, HALS are very efficient at scavenging free radicals and thus prevent these species from reacting and causing degradation of polymer chains.

Range

Hindered amines show excellent UV protection by scavenging free radicals generated by photo degradation. When to use HALS or other light stabilizers depends on the processing requirements and demands of the end user. In some cases, combinations of light stabilizers have shown superior performance.

Range

The benzophenone and benzotriazole based products are termed UV Absorbers and stabilize by 1.) preferential absorbtion of UV light and 2.) dissipating this harmful energy in a safe manner via stabilized excited states. By this mode of action these sophisticated molecules protect plastic products during their useful lifetime.

Lubricants not only have the desired result on melt viscosity, but often have other beneficial effects such as smooth, glossy surfaces on the finished article and improved dispersion of pigment and fillers.

Particularly relevant in wire and cable applications, oxidative degradation can be accelerated by copper and/or other metals present in or in contact with polymers. The addition of a metal deactivator counteracts this process and enhances the stability of polymers in e.g. cable insulation such as polyolefins and PVC.

Nucleating Agents give a higher degree of crystallinity to polymers, resulting in improved mechanical properties such as hardness and flexural modulus. Clarifying agents have the additional benefit of also improving optical properties, in particular transparency.

By using an antistatic agent, problems such as dust pick up, handling difficulties and electrical discharge will be reduced or eliminated.

ADEKA Polymer Additives Europe also offers complementary products.

Please contact us for more details.